Why quality is the key

to (virtually) everything …

Visitors from outside of our field often ask us why we spend so much time and effort on quality, why we do so much measuring, testing, analysing, checking, comparing … it’s mostly costing money, isn’t it?

Why is quality management necessary

in the first place?

The introduction, implementation, and expansion of a particularly rigid quality management are a very decisive factor for MCT’s success.

We have put this system into place because we have a high reputation in the market and want to build on our good image – quality is in demand, and we stand out from the competition with a special level of quality. We also manufacture high-precision products, which is impossible without the quality to match.

We naturally bear product responsibility as well: Our products usually need to prove their value under the toughest conditions day after day for many years or even decades; large sums of money, jobs, and at times even human lives depend on their long-term operational capability and resilience. Quality equals protection and safety in this context.

Quality helps us categorise and harness our extensive knowledge of materials and processes. It also is the basis for further and new developments, of products as well as of processes.

All these are reasons why quality management is indispensable for us and makes all the difference.

How do we

understand our quality management?

When we speak of quality management, we are talking comprehensively. We not only focus on the strict quality of our products: This is also about machines, and even about production processes and going all the way to the general attitude towards the value of our own work.

What does our

quality management look like?

Quality management starts at the leadership level for us: This is where the foundation is laid, where the cornerstones are determined and where the direction is set. Corporate management has. therefore, developed a quality strategy that clearly defines how, where, and why quality enjoys a high priority in our company – but also in our dealings with partners, suppliers, customers, institutions, and authorities. It is even more important that this positioning is reflected in practice … and that is exactly what we do.

This attitude is reflected in the MCT process management, where all of the company’s processes are defined. Since we have taken our employees onto this path from the very beginning, these requirements are implemented conscientiously and in an exemplary manner in everyday work.

Our process management is, of course, in line and in direct coordination with the requirements of the certifications to which we have subjected ourselves, including in particular the ISO 9001:2015 and ISO 13485:2016 standards. Material and manufacturing documentation are just as much a part of this as regular audits to verify employee knowledge, or targeted further education to increase it are – we believe in the principle of lifelong learning.

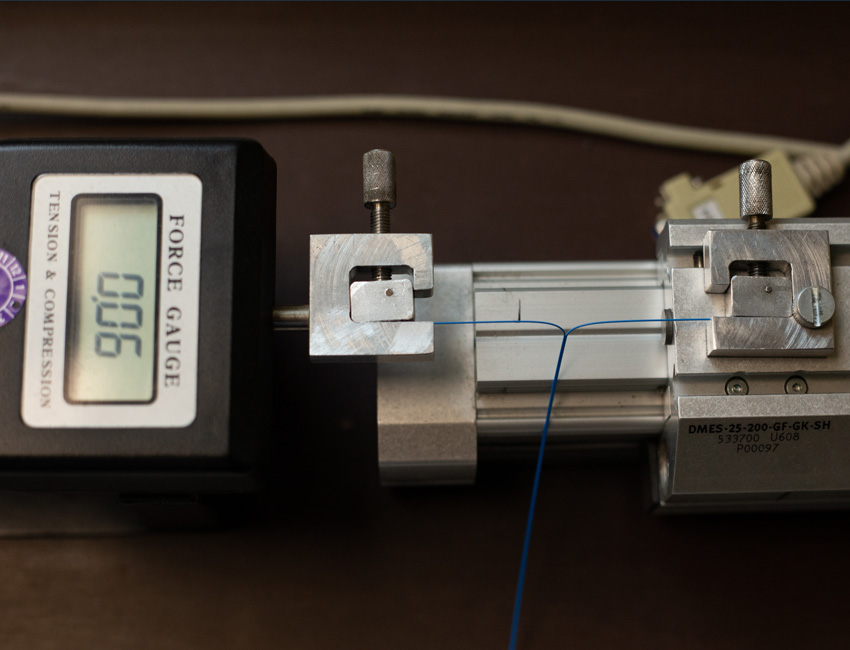

Again, “one step down”, we find ourselves at the material or manufacturing level, where MCT’s understanding of quality is expressed in detailed testing, operating and maintenance instructions for every single production step. All products go through cleaning, manufacturing, and control procedures that are as seamless as they are strict. State-of-the-art measuring and control stations are placed in many points along the production process: Among other things, breaking and tearing strength, pliability, and other stress factors are tested here – as high surface quality is time and time again. To put it in a nutshell: We check everything that reaches our factory … we inspect and document all production steps in our company … and we analyse everything before it leaves our factory again as a finished product. We work as a self-enclosed system.

We are aware of this responsibility. As a result, we place the highest demands on the quality and safety of our products to always guarantee it not only through procedures integrated into the production process, but also through external inspection and certification of our products, constant innovation, and further development. The various functional properties with which our products are equipped based on customer requirements are, of course, also reviewed along the production chain to ensure that everything is just as desired in every single batch: rustproof, acid-, UV-, chlorine-, and seawater-resistant, flexible, always cut-resistant, and twist-free …

Quality in constant

optimisation

This highly complex quality system is not rigid, however, since we keep incorporating improvements into the overall process and integrate them as soon as they have proven their worth. Such optimisations may concern materials, production steps, or even entire processes – they can originate from our development department or our laboratory, but also be suggested by employees via our internal suggestion management. Our employees’ high level of professional training pays off here, as does their identification with the company and the corresponding commitment.

The high level of personal responsibility of our employees and department heads means that many smaller development steps never actually appear in any planning documents, which tend to be designed for years: We don’t need a dedicated board resolution to adjust the quality right at the machines on site. The “Kaizen” philosophy of constant improvement flowing into the production process, which originated in Japan, could not be implemented any better…

Quality in black on white

Thus, the quality of our products as well as the efficiency and reliability of our production often become our actual proof of quality with customers as well as prospective customers.

Where defined standards and levels are stored in a more comprehensive sense, we can of course present certificates and awards.

Address

Herborner Straße 61

D-35614 Aßlar

Phone

+49 (0) 6441 / 569100 – 0

info@medicalcable-tec.com

Opening hours

Mon – Fri 08:00 AM – 06:00 PM