Production „made in Aßlar“ –

and how to benefit from it!

Our factory is located in Aßlar near Wetzlar in central Hesse, about 70 km north of Frankfurt/Main. We have concentrated all work steps and processes in this place. Our site is steeped in tradition – and quite deliberately staying in Germany.

A single site:

How does this benefit our customers?

We eliminate the need for logistics between individual processing steps by bringing all or our services to one place: Products go through the entire manufacturing process in a single pass here, no matter the specifications posed to them. This enables more efficient, faster, and more cost-effective production with significantly lower risk of failure. We have full, sole control over every step of the process, which contributes to exceptional quality.

We also offer our customers additional security with our location in Aßlar. We are always close by and able to react quickly: This advantage cannot be valued highly enough for everyone whose business depends on reliability and dependability, in particular in light of the global situation and clearly vulnerable international supply chains.

Your advantage: our highly qualified employees

Technology is important – but to us, the people who master it, in some cases even develop it further, and make the best of the manifold possibilities, are even more so.

Our market position and high reputation are, therefore, primarily due to our employees: highly qualified, with many years of experience, and always up to date due to professional training and further education. Highly efficient, motivated and committed, thoughtful and prudent, always ready to lend a hand when needed …

The team at MCT strongly identifies with the company: Some of our skilled workers are working for us in the second or third generation already. We offer a consistently positive attitude, obviously also resonating with our customers – this is how we explain the particularly high proportion of loyal regular customers, who in turn can rely on our commitment and expertise without compromise.

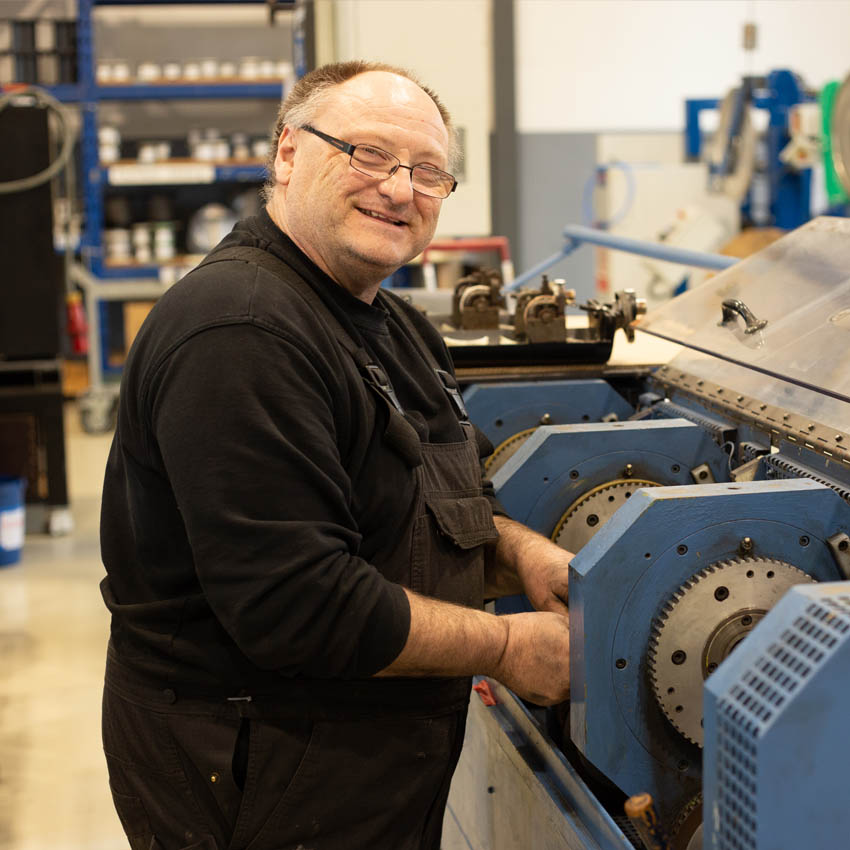

State-of-the-art machines and the

know-how to match

Our employees have access to comprehensive and state-of-the-art technology. The machinery available at MCT is versatile, enabling us to cover sequences of several manufacturing steps in a single, longer production chain.

Keeping the large number of different machines up to date at all times is of particular relevance to us: After all, we know the machines, manufacturing processes, and overarching structures so well that we are also able to develop new, innovative processes and applications together with our customers.

Some production methods are only available from us. Our technical status is so specialised that we also perform all periodic maintenance and repair work ourselves to match our own high quality and testing requirements.

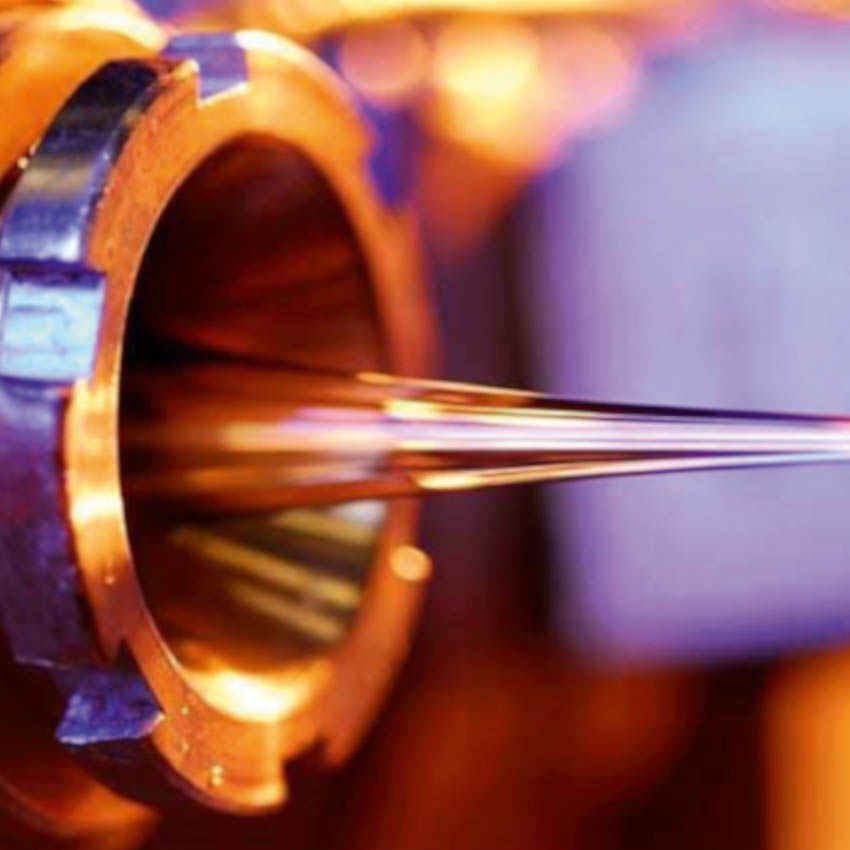

Protected cables and ropes:

in-house extrusion

An optimal, individual solution for our customers often extends beyond the actual cables and ropes. This is because the cables and ropes often need to be protected from many different environmental influences, including moisture, depending on the place of use. Insulation may be necessary to prevent or reduce contact with adjacent ropes and cables or even other materials. Our products then require a kind of protective layer – a coating to extend service life when the ropes are subject to alternating bending stresses. We can apply this by extrusion. Various techniques and materials are at our disposal for this.

The process used will be determined based on the properties that the end product is to have on the one hand, and the material used on the other: Not every material can be used in every process. Expertise is necessary here as well. Our experienced specialists are familiar with all the product properties and will find the perfect sheathing for every use of the extruded cable or rope.

Eternal flexibility:

assembly of cables and ropes

Our products meet a specific purpose where they are used: They connect elements or keep them together. This often requires connections at the cable or rope ends. We also assemble these end pieces in accordance with the wishes and needs of our customers.

We connect wires, strands, ropes, and other cables to each other with eyelets, sleeves, thimbles, nipples, springs, and many other terminals and connecting elements.

We use various assembly techniques for our ready-made products. Attachment is possible, for example, by cutting-clamping, soldering, or crimping processes – depending on the intended use of the cable or rope and its material.

Learn more about assembly here. Of course, you may also ask our experts: We will be happy to answer your questions!

Address

Herborner Straße 61

D-35614 Aßlar

Phone

+49 (0) 6441 / 569100 – 0

info@medicalcable-tec.com

Opening hours

Mon – Fri 08:00 AM – 06:00 PM